Micro silica fume

①Appearance and basic chemical composition:

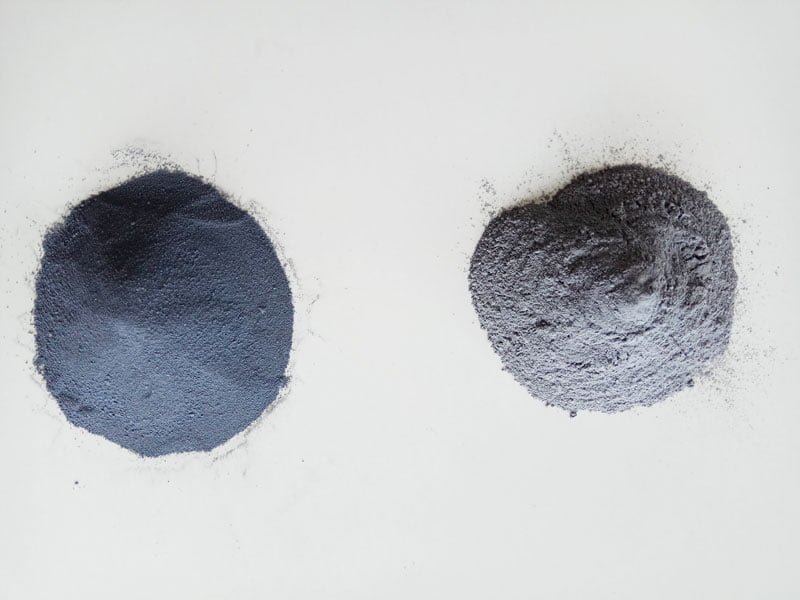

Appearance is gray or off-white powder, refractoriness > 1600 ℃. Bulk density: 1600~1700 kg/cm3.

The chemical composition is as follows:

SiO2 content: 75~98%

Al2O3 content: 1.0±0.2%

Fe2O3 content: 0.9±0.3%

② Fineness and specific surface area:

The fineness of silica fume is less than 1μm, accounting for more than 80%, the average particle size is 0.1-0.3μm, and the specific surface area is: 20-28m2/g. Its fineness and specific surface area are about 80 to 100 times that of cement and 50 to 70 times that of fly ash.

③Particle morphology and mineral phase structure:

During the formation process of silica fume, due to the action of surface tension in the process of phase transition, amorphous spherical particles of amorphous phase are formed, and the surface is relatively smooth, and some are agglomerates of multiple spherical particles sticking together. Materials mixed with silica fume, tiny spherical bodies can play a role in lubrication.

For more detailed information, please refer to : What is silica fume?

Fumed Silica

CAS Number: 112945-52-5

Molecular formula: O2Si

Molecular weight: 60.08430

Density: 2.3

Boiling point: 2230ºC

Melting point: >1600°C

Appearance: white powder

Solubility: Insoluble in water, acids and organic solvents

Its particle size is small, so the specific surface area is large, the surface adsorption force is strong, the surface energy is large, the chemical purity is high, the dispersion performance is good, the thermal resistance, resistance and other aspects have specific properties. Its superior stability, reinforcement, thickening and thixotropy make it

play an irreplaceable role in many disciplines and fields.

Characteristic:

◇As liquid thixotropic agent and thickener, it can prevent sedimentation and sag;

◇Improve the suspension and dispersion of pigment fillers in liquid systems;

◇Used as dispersing and grinding aids;

◇Improve the corrosion resistance of the coating;

◇Improve powder fluidity and storage stability;

◇Improve powder charge and charge stability;

◇Improve water resistance;

◇Improve the scratch resistance of the paint film;

◇Improve the vividness of color;

◇Fixed special effects;

◇Improve the physical and mechanical properties of the paint film;

◇Improve the adhesion and flexibility of the paint film;

◇Improve rubber, the viscoelastic properties and reinforcement, elastomers;

◇Defoaming effect in defoamer;

◇Improve the surface hardness and scratch resistance of the coating;

◇Prevent adhesion in films and elastomers;

◇As adsorbent and carrier;

◇For inkjet printing coating;

◇As high-grade filler for dental materials;

◇As catalyst carrier, remarkable thermal insulation properties for low temperature and high temperature insulation.

Silica fume vs fumed silica are completely different substance. Color, material content, physical properties, chemical properties and applications are completely different.